How to create a best cellar

Every great pint starts in the cellar, according to Jerry Shedden, category and trade marketing director at Heineken UK, making a strong cellar management game an integral part of any pub’s success.

“Research suggests 29% of cellars are unclean – and as the cellar is to beer and cider what the kitchen is to food, it’s important to keep it spotless,” he says.

“In addition, research shows that almost half of consumers (49%) wouldn’t order the same drink again if they felt their first wasn’t up to scratch and, even worse, over one third of customers will go elsewhere if the quality of drinks served is poor.

“With the huge impact that social media has on today’s on-trade, online and word-of-mouth recommendations have never been so important.

“As such, quality is of utmost importance to attract and retain customers, meaning good cellar management and staff training is an investment worth making.”

Here are some hints, tips and services to help manage your pub’s cellar:

Careful beer management

“Our cellar management is impeccable,” according to Jemima Withey of the Turks Head in Woodbridge, Suffolk – a finalist in the Best Freehouse category at the 2019 Great British Pub Awards.

“All our staff do a cellar management course. Temperatures are checked regularly, and it is very clean. We are careful with our beer management and ordering to make sure there is a minimum of wasted beer. This is fundamental to having a profitable pub.

“I have always been taught that you must store nothing in the cellar other than beer because of the risk of tainting the flavour, so that’s all that’s in there. Yes our low alcohol range and volume has increased but this is not likely to have an impact on cellar management anytime soon.

“We were looking to reduce our chemical use as much as possible and we now use ‘Clear Brew’ to clean our lines. It is a company that come in every three weeks. Their system means we need a full clean less often, so there are less chemicals, less lost beer and less man hours used.”

Cellar impact of low and no

According to John Taylor, managing director of chemical distributor and agent Chemisphere, new product innovation in the beer sector – from low-ABV pours to craft brews – could potentially put extra pressure on operators to run a clean and efficient cellar.

“Trend-wise, the increase of low and no-alcohol beers – and the ever evolving craft beer movement – means that cellars could see an increase in lines to accommodate demand, making it even more important to ensure the cellar is always clean and at the correct temperature,” he explains.

What’s more, Henry Stephenson, managing director at catering equipment supplier Stephensons adds: “We’ve tended to see that most non-alcoholic beer available is sold in cans or bottles. This means cellar space should be as accommodating for bottles as it is for kegs.”

Chemical reaction

Yet, for Taylor, the primary cellar issue facing publicans is line cleaning. “This is probably the most important part of cellar management,” he explains. “But many publicans cut corners, do not spend enough time cleaning the lines – or don’t clean them at all.

“If you spend time and use the correct chemicals – not cheap ones from the cash and carry – you will have excellent quality beer, you will retain customers, save waste and have an easier life.

“It’s also a good idea not to use the cellar for storing foodstuffs, as this can increase the chance of contamination in the dispense lines.”

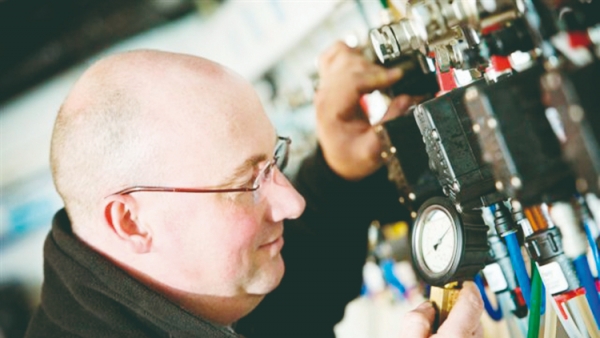

Keeping a healthy python

St Austell Brewery trade marketing manager Marc Bishop believes that one of the most common cellar errors is mismanagement of the ale python. “Many licensees are not familiar with the ale python control unit and, therefore, it isn’t topped up with water as regularly as it should be,” he says.

“Ale pythons are not always typically available in some free-trade pubs and pub groups, but they do ensure cask ale is served at the correct temperature.

“We ensure that all our tenanted and managed pubs have ale pythons as a standard piece of equipment because it is key to enhancing the quality of cask beer that we’re serving our customers.”

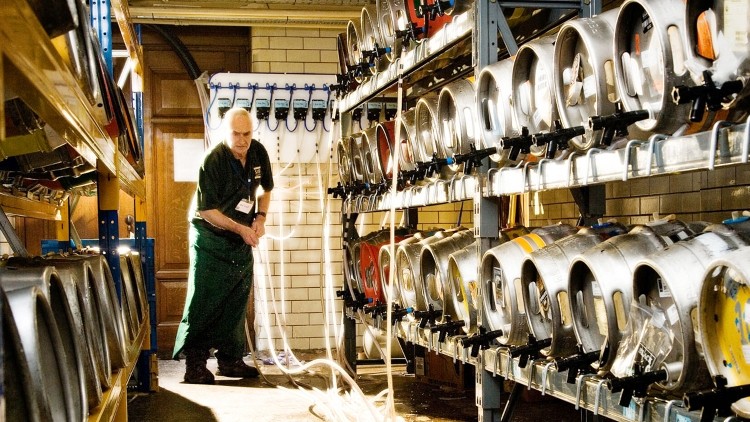

Line cleaning

Established more than 30 years ago, beer line cleaning company Beer Piper will launch its new BP4 system in 2020. Technology it believes will be a game-changer.

Beer Piper’s BP4 system logs when and who cleans the lines, and features cloud-based tech and a mobile app allowing bar managers access to real-time data.

What’s more, it ensures that beer lines are cleaned at regular intervals with environmentally friendly chemicals and eliminates the need for time-consuming line cleans freeing up pub staff to focus on customers.

Smart dispense

“Born from a ‘passion for quality and sustainability’, SmartDispense delivers consistently better draught beer and cider by keeping it cold and away from light,” according to Heineken’s Jerry Shedden.

“Traditional UK systems have bare beer lines running from cellars cooled to 12°C. SmartDispense uses green cooling (hydrocarbon) technology to cool beer towards 0°C and is extremely well insulated from keg coupler to tap, giving -3ºC in glass, a refreshing temperature preferred by consumers.

“This also means that residual beer and cider in the lines does not need to be pulled through at the start of a session, thus reducing wastage. The first time the beer sees light after being put in the keg at the brewery is when it reaches the glass. This insulation works in balance with efficient cooling, reducing energy loss for a greater environmental result.”

Green credentials

“All bottles, cans and plastics need to be recycled where possible,” according to Chemisphere’s Taylor. “If your local authority doesn’t offer recycling for certain materials, it is possible to work with specialist firms that can arrange this for you to ensure that you are being as environmentally conscious as possible.

“Regarding waste, there is a lot of water wastage when cleaning beer lines, so publicans can look at alternative cleaning solutions that extend the cleaning process to two weeks, reducing water waste by 50%,” he adds.

“And always make sure that glass washers and dishwashers are only used when they are full, so avoid half loads.”

Stephenson adds: “To reduce your carbon footprint, try buying from a local brewery. There will be less travel miles and your customers in turn will appreciate the support of local businesses.”

Staying cool

“With regards to the cellar itself, publicans must ensure that the cellar is not exposed to coolers that give off heat, thus heating the area you are trying to cool,” Taylor advises. “Staff members must also be trained to ensure that all doors are always closed so you do not let the cold air escape.

Heineken’s Jerry Shedden advises that cellars – and the beer hosted – are kept at a constant temperature of 11-13°C.

“If the cellar is too cold, cask ales will be flat and may have a chill haze,” he says. “And if too warm, the beer may develop a fob, which causes wastage – inexperienced bar staff can pour good beer into the drip tray when there is too much fobbing, which equates to almost £1,300 in lost revenue per year, per tap.”

According to Shedden, simple steps publicans can take to achieve efficient cellar cooling include using a wall mounted thermometer, regularly topping- up cooling equipment with water, checking fans and condensers are free from dust and blockages and keeping a planned schedule of maintenance to avoid costly breakdowns.

Inventory management

While connecting pubs with real ale, craft beer and cider drinkers, the Real Ale Finder app offers publicans cellar inventory management, tools and reports for pubs alongside up-to-date information with push notifications for drinkers.

Stop whining about cellar space

London-based start-up Garçon Wines has given the traditional 750ml wine bottle a lightweight and space saving rethink to reduce logistics costs, CO2 emissions and the amount of room it takes up in pub cellars.

A standard pallet can carry nearly 2.5 times more 100% recycled and recyclable Garçon bottles than the round, glass alternative meaning that publicans could use the revolutionary flat bottle to save 40% cellar space and not have to drop volume stocked.

Cellar standards

“Another missed opportunity to ensure consistent quality is by not being thorough enough when it comes to cleaning equipment between uses,” St Austell’s Bishop explains.

“If pubs are using auto tilt stillages, they need to make sure that they are thoroughly cleaned in order to operate correctly. If not, it can become sticky and won’t work smoothly – which, ultimately, disturbs the sediment in the cask.”

“A great cellar should be as clean as a walk-in fridge,” Shedden concurs. “Don’t forget to clean the ceiling and walls, as well as the floors and lines.

“Unclean cellars mean the surrounding air is dirty; this is particularly dangerous for cask beer, which draws in a pint of air with every pint poured and puts it at risk of contamination from wild yeast and bacteria.

“Avoid using strong-smelling or chlorine-based products when cleaning because this can affect the taste of the beer.”

What’s more, Shedden adds that dirty utensils and nozzles could have knockon effects and warns that they could not only damage the taste of the beer, but that overnight soaking can contaminate cellar air.

“Rinse equipment under warm running water to remove the beer residue and then leave to soak for 10 to 20 minutes in water with a sanitising tablet,” he advises.

“Never soak nozzles in soda water because this helps the bacteria to thrive and multiply. Always rinse utensils and nozzles under cold water before use. Fixed spouts should be cleaned with a stiff brush, sanitiser spray and then left to dry.”

Size, over-tapping and gas

Shedden also advises publicans to turn off the gas supply to service areas between trading sessions. “This will prevent the keg becoming over-carbonated and minimises the health and safety risk of a CO2 leak in a confined space,” he explains.

“Over-carbonation upsets the equilibrium, or optimum gas levels inside the keg, which can result in fobbing and wastage.”

Finally, he suggests that a great cellar should be the correct size for the volumes being sold. “Over-tapping has a negative impact on the quality of the beer and quality of the cellar,” he says.

“In addition, over-tapping is costly for an outlet, with each under-used tap costing £500 a year. Right-sizing your cellar will also increase energy efficiency, as you are cooling a smaller space.”